Technical Information Note

Optimising the usage of SEM Sputter Targets

Introduction

In an SEM sputter coater for coating non-conductive SEM samples, a plasma is created at a vacuum level of around 2x10-1 to 2x10-2 mbar by applying a high voltage between the grounded sample stage and the target. Argon is used as sputter gas and the gas pressure is maintained by using an adjustable needle valve to control the flow of Argon gas whilst the chamber is being pumped at the same time. It is advisable to flush the vacuum chamber twice with Argon gas before setting the required vacuum level. Argon is an inert gas and will not react with the sample or the target materials. It is also a relatively heavy gas and therefore more effective for sputtering. In modern sputter coaters a magnet is used in the target head (behind the target) to contain the plasma close to and in front of the target. A grounded dark space shield surrounds the target head.

The plasma consists of positive Argon ions and electrons. The positive Argon ions bombard the target to remove materials which is subsequently deposited on the specimen (and other parts of the sample chamber). In well designed systems, the electrons are mainly collected by the dark shield.

In some applications, such as gold coating non-conductive samples for table top SEMs, air can be used as process gas.

Sputter parameters

When using a sputter coater, there are multiple variable parameters which influence the deposition rate, sputter process and coating quality:

- Sputter current

- Sputter voltage

- Pressure (vacuum) in the sample chamber

- Distance from target to sample

- Sputter gas

- Target thickness

- Target material

- Sample material(s)

With so many different variables, it is near to impossible to calculate the deposition rate. It is better to use a thickness monitor to measure the actual deposited coating thickness.

Note: Sputter rate is measure of the amount of material removed from the target. Deposition rate is the amount of target material deposited on the sample surface.

Optimising the usage of a sputter target and reducing sputter target costs

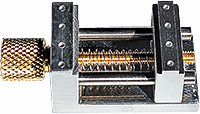

In modern DC magnetron sputter coaters, an annular magnet behind the target contains the plasma in a doughnut shape and the high voltage used is below 1 kV. This creates a highly efficient sputtering process with few electrons reaching the sample surface with no thermal damage. The drawback of this design is a preferred area on the target where target material is removed; it resembles a race track. Only a small percentage of the target is used before the plasma has “eaten” through the target. This signifies that the sputter target needs to be replaced, although only a small amount form the target is effectively used to coat the sample. Here are some simple and easy tips to increase the usage of a sputter target:

- Reduce the distance from target to sample – a shorter distance results in higher deposition rates

- Reduce the coating thickness – resistivity of sample materials can differ greatly. A coating thickness just enough to enable non-charging imaging is all that is needed. No need to coat each sample with a shiny gold layer

- Use a thickness monitor to measure the optimum coating thickness – this will lead to substantial cost savings

- Coat multiple samples in a coating cycle – one or twelve samples uses the same amount of material from the target

- Reduce the pressure of Argon in the sample chamber – less argon causes less scattering and more efficient coating with lower loss to the sample chamber walls

- Consider using a different low cost coating material when possible. For low and medium magnifications, Silver is an excellent low cost alternative (and can be removed easier as well)

- Use Argon instead of air as sputter gas – argon is more efficient

- Clean the target surface outside the racetrack area – maintain conductivity of the complete target area

- Use thicker targets – twice the thickness results in approximately 15% more material and thicker targets are less expensive per weight resulting in in an overall cost efficiency of 25-30%.