EM-Tec metal wires and materials for vacuum evaporation

EM-Tec carbon rods for carbon evaporation

EM-Tec quartz crystals for thickness monitors

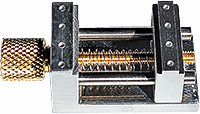

EM-Tec metal wires and materials for vacuum evaporation

high purity materials for EM sample preparation

Examples:

Introduction

The EM-Tec high purity wires are especially selected for vacuum coating of EM samples. The wires can be easily cut to size and used in evaporation coils, boats or filaments. The small amount of material and the relatively large contact area with the evaporation sources enables evaporation with low power evaporation power supplies.

For shadowing applications used with TEM samples, the thin metal wire could be wound around the end of the carbon rods to simultaneously evaporate metal and carbon.

Due to the high melting temperature, the tungsten wires can also be used to make evaporation filaments to evaporate small amounts of other metals.

Available metal wires for vacuum deposition

| Material | Symbol |

Wire Diameter |

Purity |

Aluminium |

Al |

0.7 / 0.9 mm |

99.9 % |

Copper |

Cu |

0.2 mm |

99.9% |

Nichrome 60, 60/16/24 wt% Ni/Cr/Fe |

Ni / Cr / Fe |

0.25 mm |

99.5% |

Nichrome 80, 80/20 wt% Ni/Cr |

Ni / Cr |

0.25 mm |

99.5% |

Silver |

Ag |

0.2 mm |

99.99% |

Tungsten |

W |

0.1 / 0.2 / 0.5 mm |

99.95% |

Ordering Information for EM-Tec metal wires for vacuum evaporation

|

|

|

|

|

|

|

|

|