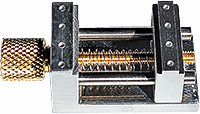

R D Mathis Chromium plated tungsten rod evaporation sources

R D Mathis Chromium plated tungsten rod evaporation sources

compact, low power and efficient way to evaporate chromium

Introduction

Chromium is typically used as an intermediate adhesion layer for gold, platinum or silver on silicon wafers or glass plates. Using chrome chips, chromium is relatively difficult to evaporate in a vacuum system due to its high melting point and high power requirements.  The chromium plated tungsten rods offer an effective, user friendly way to thermally evaporate chromium. The chrome plated tungsten rods are used for depositing thin films of chromium in high vacuum thin film coating systems.

The chromium plated tungsten rods offer an effective, user friendly way to thermally evaporate chromium. The chrome plated tungsten rods are used for depositing thin films of chromium in high vacuum thin film coating systems.

The chromium plated tungsten rods offer a better thermal efficiency, low power requirements, better control over film thickness and elimination of spitting and spalling. The tungsten rod diameter is 1.27mm with 0.25mm chrome plating. They are available in 51, 102 and 152mm length to accommodate the most popular evaporation source holders. Useful for:

- lower power systems

- systems with smaller vacuum chambers

- thin film processes that require small amounts of evaporant

- small amounts of expensive materials

- R & D and product development applications

- sample preparation applications

# Number |

Length L |

Ends C&D |

Rod Ø A |

Chrome Ø B |

Volts |

Amps |

Watts |

Temp |

72-CRW-1 |

51mm |

12.7mm |

1.27mm |

1.78mm |

1.05 |

78 |

82 |

1800 °C |

72-CRW-2 |

102mm |

12.7mm |

1.27mm |

1.78mm |

2.02 |

78 |

158 |

1800 °C |

72-CRW-3 |

152mm |

12.7mm |

1.27mm |

1.78mm |

2.40 |

77 |

185 |

1800 °C |

Ordering information for chromium plated tungsten rod evaporation sources.

|

|||||||||||||||||||||||||||||||