Micro-Tec stainless steel vacuum chambers for degassing

Micro-Tec stainless steel vacuum chambers for degassing

Ideal for degassing epoxy resins, silicones and extracting hydrocarbons

Micro-Tec stainless steel vacuum chambers for degassing

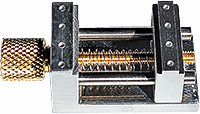

The Micro-Tec VC series stainless steel vacuum chambers have been designed for degassing cold metallographic embeddings, epoxy resins, urethane compounds, silicone rubber and/or extracting hydrocarbons from SEM samples or samples prepared with double sided tape or tabs. They are ideal for metallography, microscopy, R&D labs and/or small production facilities. The Micro-Tec VC series stainless steel vacuum chambers are equally suited to store specimens or parts under vacuum since they are capable of holding vacuum for at least 3 months (depending on outgassing of the specimens). We advise to pump vacuum once a month to maintain a lower pressure.

The pumping and venting lines are integrated in the clear transparent lid together with an indicating vacuum gauge. Both the pumping and venting line include a ball valve for quick opening and closing. The venting line also includes a filter muffler for noise reduction and clean venting.

Cold embedding resins, epoxy resin or silicon rubber mixtures should be degassed to remove air bubbles from the material by pumping and venting. The transparent lid allows for easy observation of the degassing process – in case of too much frothing, the chamber should be vented.

The vacuum chambers can also be used to extract/reduce hydrocarbons in SEM samples. By placing the samples in the vacuum chamber and pumping vacuum, hydrocarbons can be partly removed before placing the samples in the SEM. This can reduce contamination on the sample surface. Useful for adhesives or filters with oil. Not suitable for solvents like acetone, MEK and other solvents not compatible with acrylic (PMMA) material.

Features of the Micro-Tec stainless steel vacuum chambers:

- Made from robust stainless steel with transparent lid

- Integrated vacuum gauge indicator in lid

- Pumping valve with hose connector

- Venting valve with filter muffler

- Sturdy soft silicone seal area on lid

- Easy process control through clear lid

Specifications of the Micro-Tec stainless steel vacuum chambers:

Product # |

13-004190 |

13-004192 |

13-004194 |

Volume |

3 ltr |

6 ltr |

12 ltr |

Chamber diameter |

180 mm |

195 mm |

230 mm |

Chamber height |

125 mm |

200 mm |

250 mm |

Lid diameter (incl. seal |

220 mm |

220 mm |

285 mm |

Total height |

275 mm |

335 mm |

365 mm |

Weight |

1.5 kg |

2.5 kg |

3.9 kg |

Hose connection to pump |

Ø10 mm |

Ø8 mm |

Ø10 mm |

Lid material |

Acrylic |

Acrylic |

Hardened glass |

Wall thickness / material |

1.5mm stainless steel |

||

Seal |

Soft silicone rubber |

||

Integrated vacuum gauge |

0 to -1 Bar (0 to -30 inch Hg) |

||

Service temperature |

5 - 70 °C |

||

The Micro-Tec stainless steel vacuum chambers are available as standalone unit or as a set with the Micro-Tec MP950D dual stage oil-free diaphragm pump (Vacuum >50 mbar and pumping speed 60L min)

Ordering information for the Micro-Tec stainless steel vacuum chambers

|

|

|

|

|

|

|