Cressington 108 series automatic SEM carbon coaters

Cressington 108 SEM Sputter Coaters

Cressington 108 vacuum pumping system

Cressington Rotary-Tilting and Rotary-Planetary-Tilting sample stages

Cressington MTM-10/20 thickness monitor/controller

Carbon rods for the Cressington carbon coaters

Consumables for Cressington coaters, thickness monitors and pumping systems

Cressington 108 series automatic SEM carbon coaters

compact, easy to use, practical carbon coaters for analytical SEM applications

Introduction

The Cressington 108 carbon coaters are highly advanced, compact bench top carbon evaporation systems. They have been designed for analytical applications in standard SEMs and table-top SEMS. With the Cressington 108carbon, a thin and layer of conductive carbon can be evaporated on non-conductive SEM samples to enable enhanced backscatter electron imaging, cathode luminescence imaging and precise EDS/WDS analysis. The thin carbon layer with its low atomic number is electron and X-ray transparent.

The Cressington 108 carbon coaters include a sophisticated, feedback controlled power supply and a reliable Bradley carbon rod source. The carbon rods used are high purity stepped carbon rods. The stand-alone Cressington 108 series carbon coaters are preferred above systems which use carbon coating and gold sputtering in a single chamber. Stand-alone and dedicated carbon coaters do not present any contamination issues and offer high quality, high purity carbon coatings. There are two Cressington 108 carbon coating units available

- Cressington 108Carbon/A carbon coater with digital controls and standard size chamber

- Cressington 108Carbon/A/SE carbon coater with the larger sample chamber

All instruments are compatible with 230V / 50Hz.

Specification of the Cressington 108 series SEM carbon coaters

Carbon coater |

108carbon/A |

108carbon/A/SE |

Product # |

||

Operation modes |

Manual – Continuous |

Manual – Continuous |

Current |

0-200A |

0-200A |

Digital timer |

0 – 9.9sec |

0 – 9.9sec |

Voltage |

0 – 5.5V |

0 – 5.5V |

Auto vent |

yes |

yes |

Sample chamber |

Ø120 x 120mm |

Ø150 x 165mm |

Table height adjustment |

60mm |

60mm |

Sample table size |

Ø60mm |

Ø60mm |

Carbon source |

Bradley type |

Bradley type |

Carbon rods |

Ø6.15mm |

Ø6.15mm |

108 pumping system |

2.5m3/hr, dual stage |

2.5m3/hr, dual stage |

Thickness monitor |

MTM-10 optional |

MTM-10 optional |

R-T / RPT stage |

- |

optional / optional |

Power |

230v / 50 Hz / 1000W |

230v / 50 Hz / 1000W |

Cressington 108carbon/A SEM carbon coater

The Cressington 108carbon/A SEM carbon coater has been specifically designed for coating non-conductive SEM sample to enable charge-free imaging and analysis with standard SEMs and table-top SEMS. Carbon coating is preferred for applications like BSD-imaging, CL and EDS/WDS applications.

The Cressington 108carbon/A uses a unique feedback-controlled Bradley type carbon rod evaporation source. The rod source is ideal for reproducible coating thickness, thicker coatings or even multiple coatings. The advanced evaporation supply monitors current and voltage by sensor wires in the evaporation head, while the carbon source is controlled as part of a feedback loop. This arrangement gives the carbon rod source exceptional stability and reproducibility. The result is a high quality, high purity carbon coating with a lower power consumption. In manual mode, the system can be operated either with continuous or pulsed evaporation. Pulsed evaporation enables precise built-up to the desired coating thickness. In automatic mode, the evaporation source is operated with programmed voltage and time for increased reproducibility.

Vacuum is provided by the 108 pumping system which consists of a compact 2.5m3/hr dual stage rotary pump with integrated anti-vibration tray.

Optionally available is the Cressington MTM10 thickness monitor to precisely measure the coating thickness.

- Manual / automatic controls

- Compact desk top system

- Short coating cycles

- Ideal for EDS applications

|

Cressington 108carbon/A/SE SEM carbon coater

19-012050 R-T stage 19-012080 R-P-T stage

rotary-tilting stage

The Cressington 108carbon/A/SE carbon coater is based on the 108carbon/A SEM carbon coater. It includes all the advantages of the 108carbon/A, but with a larger Ø150 x 165mm glass chamber. The larger chamber allows the 108carbon/A/SE to be equipped with the optional Rotary-Tilting (R-T) stage or the optional Rotary-Planetary-Tilting (R-P-T) stage. The 108carbon/A/SE SEM carbon coater can accommodate larger samples or multiple samples on the R-P-T stage with its 4 sample holders. With the R-T and the R-P-T stages, a much better degree of uniformity can be achieved, especially on rough sample surfaces. With the optional R-T or R-P-T stage, chamber height can be varied between 165 and 250mm; the top-plate is attached to a telescopic post.

Vacuum is provided by the 108 pumping system which consists of a compact 2.5m3/hr dual stage rotary pump with integrated anti-vibration tray.

Optionally available is the Cressington MTM10 thickness monitor to precisely measure the coating thickness.

- Large sample chamber

- Optional R-T and R-P-T stage

- Improved coating uniformity

- Optional MTM10 thickness monitor

Quotation information for Cressington 108carbon/A/SE SEM carbon coater and optional stages

|

|

|

|

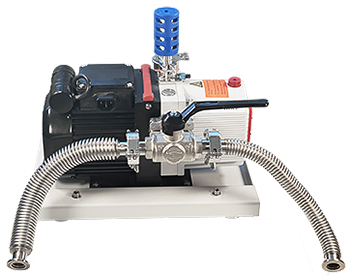

Compact, efficient, desk-top pumping systems for the Cressington coaters

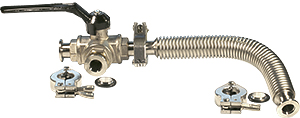

The compact, desk-top vacuum pumping system for the Cressington 108 series consists of a highly efficient direct drive 2 stage rotary vacuum pump, anti vibration tray and all metal vacuum couplings. The pumping system is placed directly behind the coater to ensure an extremely fast pump-down time of less than 30 seconds to 0.1mbar. The results are short cycle times, responsive pumping and improved coating results. There are two systems available:

Cressington 108 vacuum pumping system for 108 series coater, 230V / 50Hz

Dual-Vacset 108 pumping system to pump two 108 series coaters

- Standard 108 vacuum pumping system for a single 108 series coater

- Dual-Vacset 108 pumping system to pump two 108 series coaters

Specification of the Cressington 108 vacuum pumping system

Rotary pump type |

2-stage, high speed direct drive |

Pumping speed |

2.5m3/hr |

Ultimate Vacuum |

3 x 10-3mbar / 3 x 10-3hPa |

Vacuum flange connections |

DN16KF |

Operating temperature |

12-40°C |

Sound level @ 50Hz |

<53 dB(A) |

Pumping fluid type |

P3 |

Vacuum fluid filling |

0.4ltr |

Anti-vibration tray |

included |

Dimensions LxBxH |

33 x 28 x 30cm incl. filter |

Vacuum couplings |

All metal, quick release DN16KF |

Rated power |

150W |

Voltage |

230V / 50Hz |

Quotation information for Cressington 108 vacuum pumping systems

|

|

Ordering information for Dual-vacset upgrade kit to connect two108 series coaters to one pump 19-010410

|

Quotation information for Cressington MTM-10 thickness monitor

|

|

|