Carbon rods for carbon evaporation

EM-Tec TEM support grids

Value-Tec TEM support grids

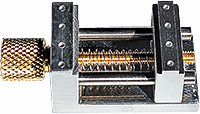

EM-Tec high precision tweezers

high purity carbon rods for EM sample preparation

Ultra-high purity carbon rods

Ultra high purity carbon rods are used for carbon evaporation in EM applications. Either to coat non-conductive samples with a thin layer of carbon or to produce support films for TEM samples. The structure of the carbon rods is in reality high purity graphite which is formed during the purification process of the rods. The maximum level of impurity for the high-purity carbon rods is 2ppm with none of the elements exceeding 1ppm. See typical statements of purity. The typical level of impurity is 1ppm or less. This makes the ultra-high purity carbon rods ideal for SEM/EDS, EBSD, WDS and EPMA applications. Currently two grades of ultra-high purity carbon rods are offered:

- Grade F-S which is the high-purity standard grade. This is the most common grade of carbon rods. The rods tend to be stronger and more brittle. Stepped points of this grade are best made with an electrical carbon rod shaper. Available in Ø3.05mm (Ø0.120”) and Ø6.15mm (Ø0.242”) with a length of 305mm (12”). Compatible with carbon coaters from Cressington, AGAR, JEOL, Quorum, Leica, Edwards , Anatech (Hummer) and Denton.

- Grade F-A which is a high purity softer grade. This is a softer grade and stepped points are somewhat easier to make from this grade, when using a hand carbon rod shaper. Compatible with coaters from Cressington (50Hz), AGAR (50Hz), JEOL (50Hz), Edwards and Denton.

Technical grade carbon rods

For less demanding and standard SEM-EDS applications, the F-S grade is also available in a technical grade T-S with a lower purity and lower cost. The technical grade T-S graphite rods can contain impurities up to 50ppm. Typical impurities with their maximum levels can be: Si 2-5ppm, Ca 20ppm, Ti 8-10ppm, V 4ppm, Cr 10ppm and Fe 20ppm.- not to exceed 50ppm total. The machinal properties of the T-S grade are identical to the F-S grade.

Carbon rod grade |

Grade F-S High purity |

Grade F-A High purity |

Grade T-S Technical |

Product# Ø3.05mm |

|||

Density (g/cm3) |

1.80 |

1.61 |

1.80 |

Electrical resistivity (µOhm.cm) |

939.7 |

635 |

939.7 |

Hardness (shore) |

42 |

32 |

42 |

Porosity (%) |

16.5 |

28.5 |

16.5 |

Tensile strength (MPa) |

41.4 |

22.1 |

41.4 |

Flexural strength (MPa) |

51.8 |

24.2 |

51.8 |

Compressive strength (MPa) |

65.6 |

48.2 |

65.6 |

Thermal expansion rate (x10-6/K) |

2.9 |

1.9 |

2.9 |

Purity |

Ultra-high |

Ultra-high |

Technical |

Impurities (ppm) |

Max. 1/element |

Max. 1/element |

Max. 50 total |

Structure |

Graphite |

Graphite |

Graphite |

Appearance |

Hard,brittle |

Softer |

Hard,brittle |

Ordering information for ultra-high purity and technical grade carbon rods grade F-S

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

The carbon rods are furnace purified; this changes the carbon into graphite and removes impurities. A statistical sample of each production batch of the ultra high purity carbon rods is analysed. (ETV-ICP Electro Thermal Evaporation – Inductively Coupled Plasma) is used for elemental analysis of the carbon rods. For each element there is 1ppm maximum allowable spot impurity.

Typical analytical results for the statement of purity in ppm for the carbon rods are:

Element |

Grade F-S Ø3.05mm |

Grade F-S Ø6.15mm |

Grade F-A Ø6.15mm |

B |

0.026 |

N/D |

0.043 |

Mg |

0.031 |

0.045 |

0.020 |

Al |

0.189 |

0.029 |

0.819 |

Si |

0.464 |

N/D |

0.081 |

Ca |

0.203 |

0.404 |

0.109 |

Ti |

0.011 |

0.004 |

0.005 |

V |

0.016 |

N/D |

0.010 |

Cr |

0.018 |

N/D |

N/D |

Mn |

N/D |

N/D |

N/D |

Fe |

0.275 |

0.034 |

0.063 |

Ni |

0.093 |

0.008 |

0.058 |

Cu |

0.012 |

0.015 |

N/D |

Zn |

0.016 |

0.113 |

0.005 |

Zr |

N/D |

0.001 |

N/D |

Mo |

0.038 |

0.009 |

0.036 |

Ag |

N/D |

N/D |

N/D |

Sn |

0.131 |

N/D |

N/D |

W |

N/D |

N/D |

N/D |

Pb |

N/D |

0.021 |

N/D |