EM-Tec conductive copper SEM tapes

EM-Tec conductive double sided carbon tape & tabs

Super smooth conductive double sided carbon tapes

EM-Tec conductive copper SEM tapes

EM-Tec premium single sided conductive copper tapes for SEM / FIB applications. Indispensable for making ground contacts between the sample surface and SEM stub or SEM sample holder. The tape is made with soft copper foil which is easily molded to follow the shape of the sample. The EM-Tec premium copper SEM tape is a highly electrically conductive tape with a conductive pressure sensitive acrylic adhesive and a paper liner. The resistance of the applied tape is < 1 Ohm with an a high initial tack to provide good adhesion. It is recommended to assert light pressure on the tape to improve conductivity. Available in the practical widths of 3, 6, 10,12, 20 and 25 mm with a length of 25m. Conductive adhesive side covered with siliconised backing paper liner. Clean 76mm diameter plastic core.

Specifications of the EM-Tec premium single sided conductive copper tape:

| Tape material | Copper, 99.98% purity |

Adhesive |

Conductive pressure sensitive acrylic adhesive |

Copper tape thickness |

0.035mm |

Adhesive thickness |

0.025mm |

Total tape thickness |

0.06mm |

Backing paper thickness |

0.14mm |

Resistance |

< 1 Ohm |

Adhesive strength |

14N / 25mm |

Tape strength |

45N / mm |

Use temperature range |

-10 to +120 °C |

Length |

25m |

Core diameter |

76mm (3”) |

Order EM-Tec premium single sided conductive copper SEM tapes

EM-Tec double sided conductive copper tape for SEM / FIB applications.

The EM-Tec double sided conductive copper tape has a layer of conductive acrylic adhesive on both sides. Highly electrically conductive with a resistance through the adhesive < 1 Ohm. This double sided conductive copper tape has the same specifications as the 3M 1182 tape. Ideal for mounting samples directly on sample stubs whilst establishing a grounding path. Either to mount large samples on stubs or for smaller samples directly on the tape. Non-conductive samples surfaces should be coated to obtain best imaging results. Can be used for long term applications. Much better conductivity than carbon tape and carbon tabs. The soft copper tape can be easily cut to the required size. Available with 6, 12, 20 and 25 mm width and length of 33m. Both side are covered with siliconised backing paper which makes it easy to unwind the tape and cut to size before applying the tape. Remove the siliconised paper from one side first; apply copper tape and then remove the other backing paper. Tip: Try to minimise the exposed area of tape in the SEM to reduce outgassing

Specifications:| Tape material | Copper, 99.98% purity |

| Adhesive | Conductive acrylic adhesive (2x) |

| Copper tape thickness | 0.035mm |

| Adhesive thickness | 0.025 +/- 0.005 mm + 0.022 +/- 0.005 mm |

| Total tape thickness | 0.082 +/- 0.01mm |

| Backing paper thickness | 0.14mm (2x) |

| Resistance | < 1 Ohm |

| Adhesive strength | 10N / 25mm per side |

| Tape strength | 45N / mm2 |

| Use temperature range | -10 to +120 °C |

Length Width |

33m Choice of 6, 12, 20 and 25mm |

| Core diameter | 76mm (3”) |

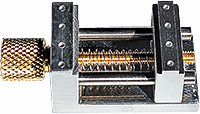

The EM-Tec double sided conductive copper tape

Ordering Information for EM-Tec single sided premium conductive copper tapes for SEM / FIB applications

|

|

|

|

|

|

|

|

|