Cressington 208C Desktop Turbo Carbon Evaporator

Cressington 108 SEM Sputter Coaters

Cressington 108 vacuum pumping system

Cressington Rotary-Tilting and Rotary-Planetary-Tilting sample stages

Cressington MTM-10/20 thickness monitor/controller

Carbon rods for the Cressington carbon coaters

Consumables for Cressington coaters, thickness monitors and pumping systems

Cressington 208C Desktop Turbo Carbon Evaporator

High vacuum turbo pumped carbon coater for SEM, FESEM, Microprobe, EBSD, EDX, WDX and TEM applications

Cressington 208C Desktop high vacuum carbon coater

Cressington-208C high vacuum carbon coater with optional MTM-10 thickness monitor

The Cressington 208C Desktop high vacuum carbon coater has been designed to make high quality carbon coatings for TEM, SEM, EDX/WDX, Microprobe, EBSD and FIB applications. The carbon evaporated in high vacuum is of a higher quality than carbon evaporated in low vacuum. It offers a near amorphous structure with high conductivity as needed for analytical applications.

The advanced, turbo-pumped systems with the practical glass chamber size of 150mm diameter offers rapid pump down with coating cycles of approx. 10 minutes. The Ø150mm glass chamber is relatively easy to clean, facilitates rapid pump down and is more practical than larger chambers or rectangular metal chambers.

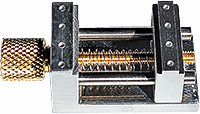

The 208C offers carbon evaporation with ultra purity carbon rods or carbon fiber threads with the optional carbon fiber thread evaporation source. The standard system includes the 150mm diameter glass chamber, turbo pumped high vacuum system, Pirani and Penning vacuum gauges, a height adjustable static sample table, the Bradley carbon source for ultra purity carbon rods and a height adjustable telescopic top plate support for the optional R-T 100 or R-P-T stages. The Cressington 208C turbo carbon coater is available with either the standard rotary backing pump or as an oil-free system with a diaphragm backing pump.

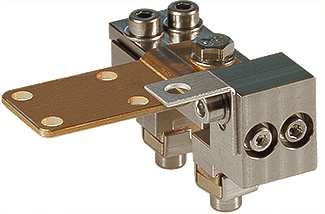

19-012050 R-T stage 19-012080 R-P-T stage rotary-tilting stage

The Cressington 208C high vacuum carbon coater can be enhanced with several options:

- The R-T 100 rotary tilting stage for coating large sample, glass slides, wafers and multiple SEM samples

- The RPT rotary planetary tilting stage with planetary sample holders for coating multiple samples for SEM, FESEM, EDX/WDX, EBSD and for uniform coating of rough surfaces

- The MTM-10 thickness monitor system for precise and/or reproducible carbon coatings

The carbon evaporation supply for the 208C turbo carbon coater:

Cressington 208C high vacuum coater features a unique, fully integrated electronic feedback controlled power control for the carbon rod fed Bradley type carbon evaporation source. The Bradley source uses the ultra-purity two-stepped carbon rods which ensures a defined diameter of the evaporated carbon and therefor reproducible settings. Current and voltage are monitored by sensor wires incorporated in the top plate where the carbon evaporation source is part of the feedback loop. This gives the conventional rod fed source exceptional stability and reproducibility.

The evaporation source can be operated in automatic “continuous” mode or two manual modes: “continuous” or “pulse” mode. The pulsed mode, when used in conjunction with the optional MTM-10 thickness monitor, gives absolute control over the desired thickness of the carbon coating. The automatic mode allows the user to set both voltage and time, which together with the two-step carbon rods, enables consistent carbon coatings with ease of use.

The Bradley source can be exchanged for the optional carbon fiber thread source which uses the same power source as for the carbon rods. The carbon fiber thread used is grade CT16 (1.6 g/m with a diameter of ~2.4 mm)

Features and benefits of the 208C turbo carbon coater are:

- Unique, voltage controlled rod source gives multiple evaporation capability

- Optional evaporation source for carbon fiber threads

- Choice of Automatic or Manual carbon evaporation

- Consistent and reproducible carbon coating

- Cylindrical glass chamber with 150mm diameter gives very rapid pump down

- Pump down time 90 seconds to 1x10-4 mbar with ultimate vacuum 5x10-6 mbar

- Pirani and Penning (HV) vacuum gauges

- Optional diaphragm pump available for oil-free operation

- Compact, space saving desktop design, No water cooling needed

- Optional R-T 100 or R-P-T stages for large samples and uniform coating

- Optionally available MTM-10 precise, high resolution thickness monitor

Specifications of the Cressington 208C high vacuum carbon coaters

Carbon coater |

208C |

208CD |

Product # |

||

Operation modes |

Automatic - Continuous |

|

Pumping system HV |

Turbo pump 67l/s |

Turbo pump 67 l/s |

Current |

0-200A |

|

Digital timer |

0 – 9.9sec |

|

Voltage |

0 – 5.5V |

|

Auto vent control |

yes |

|

Standard sample chamber |

Ø150 x 165mm |

|

Extended with RT or RPT stage |

Ø150 x 250mm |

|

Table height adjustment |

60mm |

|

Sample table size |

Ø60mm |

|

Carbon source |

Bradley type |

|

Carbon rods |

Ø6.15mm |

|

Pump down to 1x10-4 mbar |

90 seconds |

120 seconds |

Ultimate pressure |

5 x 10-6 mbar |

|

Vacuum gauges |

Pirani + Penning |

|

Dimensions (W x D x H) |

60 x 60 x 36 cm |

|

Weight incl. pumps |

45kg |

|

Power |

230v / 50 Hz / 1000W |

|

Carbon fiber thread source |

optional |

|

Carbon fiber thread |

#70-CC1016 (1.6 g/m) |

|

Thickness monitor |

MTM-10 optional |

|

R-T stage / RPT stage |

optional / optional |

|

Quotation information for Cressington 208C high vacuum turbo carbon coater

|

|

Quotation information for MTM-10 thickness monitors

|

|

|

|

|

Quotation information for the available options for the Cressington rotary tilting stages

|

|

Ordering information for Cressington 208C high vacuum turbo vacuum coater consumables

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|